| Name: | Solder Bar 50/50 (Sn50Pb50) |

| Name: | Tin Lead Solder Bar 50/50 Sn50Pb50 |

| Alloy: | Tin Lead |

| Composition: | Sn50Pb50, 50/50 |

| Form: | Solder Bar |

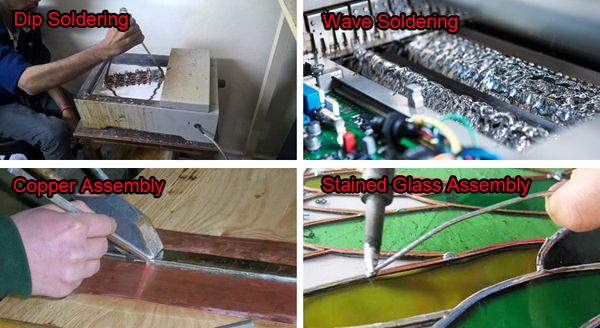

| Application: | Wave soldering, Dip Soldering, Copper Roofing Assembly |

| Place of origin: | China |

Product Description

Tin Lead Solder Bar 50/50 (Sn50Pb50)

The Tin Lead Solder Bar alloy 50/50 is known as Sn50Pb50 which means by weight 50% of the metal is tin and the remaining half is lead. This is a low to mid-range melting point of bar solders.

We accept both big orders and small orders. Big orders will be delivered by sea, small order will be delivered by courier service. Contact us, Whatsapp / Wechat:008613450770997 ; Email: xfsolder@gmail.com or xfsolder@163.com , or fill in the Contact Form in the bottom of this page.

Characteristics of Tin Lead Solder Bar 50/50

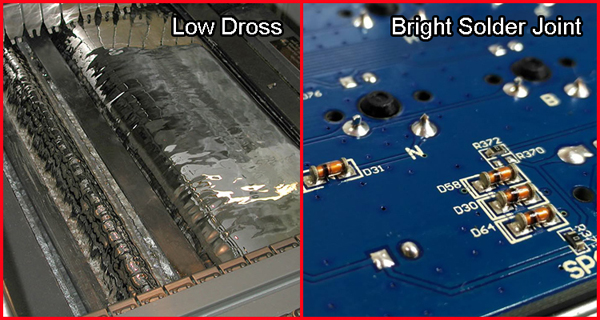

1. Melting point at 183-214℃, it's a mid-range temperature soft solder.

2. Good electrical conductivity.

3. Good wetting & liquidity properties.

4. Compatible to most flux of the major brands.

Applications of Tin Lead Solder Bar 50/50

This bar solder of Sn50Pb50 is a general purpose alloy that commonly used for copper drain piping, tin plating, seaming joints of sheet metal (copper roofing, flashing) etc, but it's illegal to use it for portable water piping because this is a leaded alloy.

Packing of Tin Lead Solder Bar 50/50

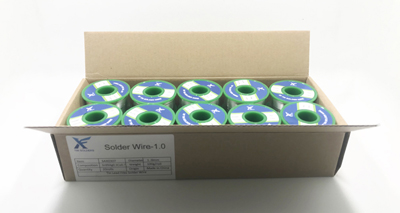

1. This alloy Sn50Pb50 is cast into bar forms.

2. Each bar at a weight of around 0.5kgs

3. Every 25kgs are packed into a carton

4. For export, we have plastic pallets to load the cartons for easy-approach for folk-lift to operate.

5. If you need special shape of the bars or customized carton, consult our sales team.

Notices for storage and handling of Tin Lead Solder Bar 50/50

1. Store the bar solder of Sn50Pb50 at dry and non-corrosive place and avoid direct sunlight.

2. The bar solders are expected to have infinitive shelf life though as time goes by, surface of the bar might turn a bit dull.

3. Use proper abrasive to remove the burrs of the surface or the grease of the surface in case of needed.

4. Read & follow TDS & MSDS.