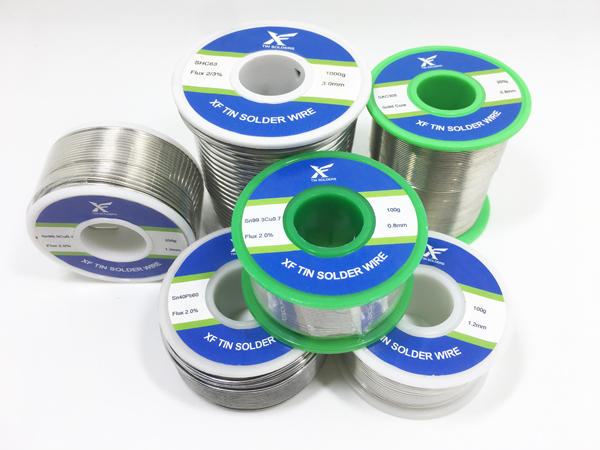

| Name: | 1.0mm Wire Diameter Lead Free Soft Solder SAC07 (Sn99.3Cu0.7) – 100g, 200g, 250g, 500g, 1kg per Roll for Medical Equipment Soldering from China |

Product Description

1.0mm Wire Diameter Lead Free Soft Solder SAC07 (Sn99.3Cu0.7) – 100g, 200g, 250g, 500g, 1kg per Roll for Medical Equipment Soldering from China

Introduction to Lead Free Soft Solder SAC07

When it comes to soldering medical equipment, precision, safety, and reliability are paramount. Lead free soft solder SAC07 (Sn99.3Cu0.7) is an excellent choice for professionals who require high-performance soldering materials without the risks associated with lead-based alternatives. This lead free wire solder is designed to meet stringent industry standards, ensuring strong, durable joints while complying with environmental and health regulations.

Available in multiple sizes—lead free soft solder 100g, 200g, 250g, 500g, and 1kg—this 1.0mm wire diameter lead free soft solder offers versatility for different applications. Whether you're working on delicate medical devices or industrial soldering tasks, lead free soft solder Sn99.3Cu0.7 provides excellent wetting properties, low melting temperature, and superior electrical conductivity.

Why Choose Lead Free Soft Solder SAC07?

1. Compliance with Medical and Safety Standards

Medical equipment manufacturing requires materials that meet strict safety regulations. Lead free soft solder SAC07 is RoHS-compliant, ensuring it is free from hazardous substances. This makes it ideal for medical soldering applications where lead contamination must be avoided.

2. Superior Performance with Sn99.3Cu0.7 Alloy

The lead free soft solder Sn99.3Cu0.7 composition consists of 99.3% tin (Sn) and 0.7% copper (Cu), offering excellent mechanical strength and thermal fatigue resistance. This alloy ensures smooth soldering with minimal oxidation, reducing the risk of cold joints.

3. Versatile Wire Diameter for Precision Work

With a 1.0mm wire diameter, this lead free wire solder is perfect for both automated and manual soldering processes. The consistent thickness allows for controlled application, making it suitable for intricate medical electronics and PCB assemblies.

4. Multiple Packaging Options

To accommodate different project scales, this lead free soft solder is available in various weights:

Lead free soft solder 100g – Ideal for small repairs and prototyping.

Lead free soft solder 200g & 250g – Suitable for medium-scale production.

Lead free soft solder 500g & 1kg – Best for high-volume manufacturing.

Applications of Lead Free Soft Solder SAC07

1. Medical Equipment Soldering

Due to its biocompatibility and reliability, lead free soft solder SAC07 is widely used in medical device manufacturing. It ensures secure connections in:

Surgical instruments

Diagnostic equipment

Implantable devices

Monitoring systems

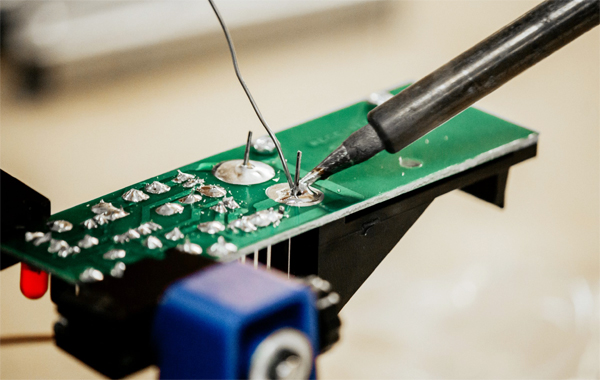

2. Electronics and PCB Assembly

The lead free wire solder is also effective in consumer electronics, automotive systems, and aerospace applications where lead-free compliance is mandatory.

3. HVAC and Plumbing

While primarily designed for electronics, this lead free soft solder Sn99.3Cu0.7 can also be used in refrigeration and plumbing systems requiring lead-free joints.

Advantages Over Traditional Lead-Based Solder

Non-Toxic & Environmentally Friendly – Unlike lead-based solders, lead free soft solder SAC07 eliminates health risks associated with lead exposure.

Better Thermal Cycling Performance – The Sn99.3Cu0.7 alloy resists thermal fatigue, making it more durable in high-stress environments.

Excellent Wetting Properties – Ensures strong adhesion to copper, silver, and other common metals used in medical devices.

Wide Availability – With options like lead free soft solder 100g, 200g, 250g, 500g, and 1kg, users can select the right quantity for their needs.

How to Use 1.0mm Lead Free Soft Solder SAC07

For optimal results when using 1.0mm wire diameter lead free soft solder, follow these steps:

Clean the Surfaces – Remove oxidation or contaminants from the metal parts to be joined.

Apply Flux – Use a no-clean flux to enhance wetting and prevent oxidation.

Heat the Joint – Use a soldering iron (recommended temperature: 250°C–300°C).

Feed the Solder – Apply the lead free wire solder to the joint, allowing it to flow smoothly.

Inspect the Connection – Ensure a shiny, smooth joint without cracks or voids.

Conclusion

For professionals in the medical, electronics, and manufacturing industries, lead free soft solder SAC07 (Sn99.3Cu0.7) is an outstanding choice. Its 1.0mm wire diameter ensures precision, while the availability of lead free soft solder 100g, 200g, 250g, 500g, and 1kg rolls provides flexibility for various applications.

By choosing lead free soft solder Sn99.3Cu0.7, you invest in a safer, more reliable, and high-performance soldering solution that meets modern industry standards. Whether you're assembling medical devices or working on intricate electronics, this lead free wire solder delivers consistent, high-quality results.

For bulk orders or customized packaging, contact trusted suppliers to ensure you get the best lead free soft solder SAC07 for your needs.

Contact Information

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997