| Name: | 0.7mm 0.9mm 1.2mm 1.6mm 2.3mm 3.2mm Sn60Pb40 Solder 500grams for PCBA |

Product Description

0.7mm 0.9mm 1.2mm 1.6mm 2.3mm 3.2mm Sn60Pb40 Solder 500grams for PCBA

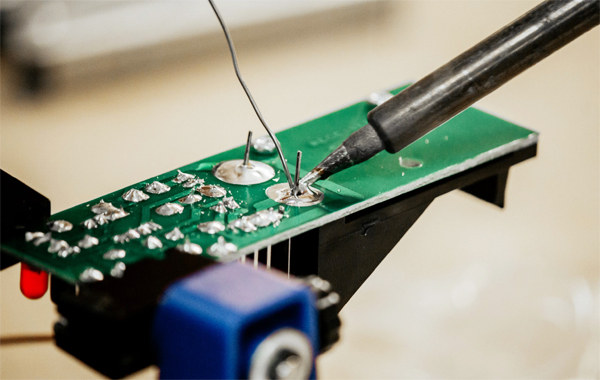

When it comes to high-quality soldering for printed circuit board assembly (PCBA), Sn60Pb40 solder remains a popular choice among professionals and hobbyists alike. This alloy, composed of 60% tin (Sn) and 40% lead (Pb), offers excellent wetting properties, strong joint formation, and reliable performance across various applications. Whether you need 0.7mm Sn60Pb40 solder, 0.9mm Sn60Pb40 solder, or thicker diameters like 3.2mm Sn60Pb40 solder, having the right wire size ensures precision and efficiency in your soldering tasks.

In this comprehensive guide, we’ll explore the benefits of Sn60Pb40 solder 500grams, the best applications for different diameters, and why this alloy is ideal for Sn60Pb40 solder for PCBA projects.

Why Choose Sn60Pb40 Solder?

Sn60Pb40 solder is widely used in electronics manufacturing due to its:

Low melting point (around 183°C–190°C), making it easy to work with.

Excellent flow characteristics, ensuring smooth and consistent joints.

Strong mechanical strength, reducing the risk of cold solder joints.

Cost-effectiveness, providing a reliable alternative to lead-free solders.

For professionals working on Sn60Pb40 solder for PCBA, this alloy ensures durable connections, especially in through-hole and surface-mount technology (SMT) applications.

Choosing the Right Diameter: 0.7mm to 3.2mm Sn60Pb40 Solder

Selecting the correct solder diameter is crucial for achieving clean, reliable joints. Below, we break down the best uses for each size of Sn60Pb40 solder 500grams:

1. 0.7mm Sn60Pb40 Solder – Precision Soldering

The 0.7mm Sn60Pb40 solder is perfect for fine-pitch components, such as:

Small SMD resistors and capacitors

IC pins and delicate connectors

High-density PCBA work

Its thin diameter allows for controlled application, minimizing excess solder and bridging risks.

2. 0.9mm Sn60Pb40 Solder – Versatile Mid-Range Option

The 0.9mm Sn60Pb40 solder strikes a balance between precision and efficiency, making it ideal for:

General PCB repairs

Medium-sized SMD components

DIY electronics projects

This size is a favorite among technicians who need flexibility in their soldering tasks.

3. 1.2mm Sn60Pb40 Solder – All-Purpose Soldering

The 1.2mm Sn60Pb40 solder is one of the most commonly used diameters, suitable for:

Through-hole components

Larger SMD parts

Automotive and industrial electronics

Its moderate thickness ensures quick soldering without excessive waste.

4. 1.6mm Sn60Pb40 Solder – Heavy-Duty Applications

For larger joints and higher heat requirements, the 1.6mm Sn60Pb40 solder is an excellent choice. It works well for:

Power electronics

Thick wire connections

High-current PCB traces

This diameter reduces the need for multiple passes, improving workflow efficiency.

5. 2.3mm Sn60Pb40 Solder – Industrial and High-Heat Soldering

The 2.3mm Sn60Pb40 solder is designed for demanding applications, including:

Large terminal soldering

Ground connections

Heavy-duty electrical repairs

Its thicker wire ensures robust joints in high-stress environments.

6. 3.2mm Sn60Pb40 Solder – Maximum Deposition Rate

The 3.2mm Sn60Pb40 solder is best for:

Large-scale industrial soldering

High-volume PCBA production

Thick metal joints requiring significant solder fill

This size minimizes refill frequency, making it ideal for automated soldering systems.

Why Buy Sn60Pb40 Solder 500grams?

Purchasing Sn60Pb40 solder 500grams offers several advantages:

Cost savings compared to smaller quantities.

Consistent quality throughout large projects.

Reduced downtime from frequent reorders.

Whether you’re a professional technician or an electronics enthusiast, having a 500-gram spool ensures you’re always prepared for any soldering task.

Best Practices for Using Sn60Pb40 Solder for PCBA

To achieve the best results with Sn60Pb40 solder for PCBA, follow these tips:

Use the Right Temperature – Set your soldering iron between 300°C and 350°C for optimal flow.

Clean Surfaces First – Remove oxidation and contaminants from PCB pads and components.

Apply Flux When Needed – Flux improves wetting and prevents cold joints.

Match Solder Diameter to Component Size – Smaller parts need thinner solder (e.g., 0.7mm Sn60Pb40 solder), while larger joints require thicker wire (e.g., 3.2mm Sn60Pb40 solder).

Avoid Excessive Heat – Prolonged heating can damage components and PCB traces.

Conclusion

Choosing the right Sn60Pb40 solder diameter—whether 0.7mm, 0.9mm, 1.2mm, 1.6mm, 2.3mm, or 3.2mm Sn60Pb40 solder—ensures efficient and reliable soldering for PCBA projects. A 500-gram spool provides ample supply for both professional and hobbyist use, making Sn60Pb40 solder 500grams a smart investment.

By understanding the strengths of each solder size and following best practices, you can achieve flawless soldering results every time. Whether you’re working on intricate electronics or heavy-duty repairs, Sn60Pb40 solder for PCBA delivers the performance and reliability you need.

For high-quality Sn60Pb40 solder 500grams, explore trusted suppliers to ensure you get the best material for your soldering needs.

Contact Information:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997