| Name: | Solder Paste |

| Name: | Solder Paste |

| Alloy: | Leaded & Lead Free |

| Packing: | Jar or Syringe |

| Flux: | No clean flux |

| Origin: | China |

Product Description

Solder Paste

Solder paste is one type of solder that is sticky

paste form in metallic grey color, mixed with alloy solder powder and flux. Solder

paste is mainly used to assemble printed circuit boards (PCB) by connecting

surface mount components (IC) to the pads on the PCB. It can hold the

electronic components in place on the board before the soldering, and after it’s

heated up the flux will be activated and the solder powder insides will melt

and then well bond the components with the PCB. Solder paste are available in

tin lead alloys & lead free alloys.

Basic Product Information of Solder Paste:

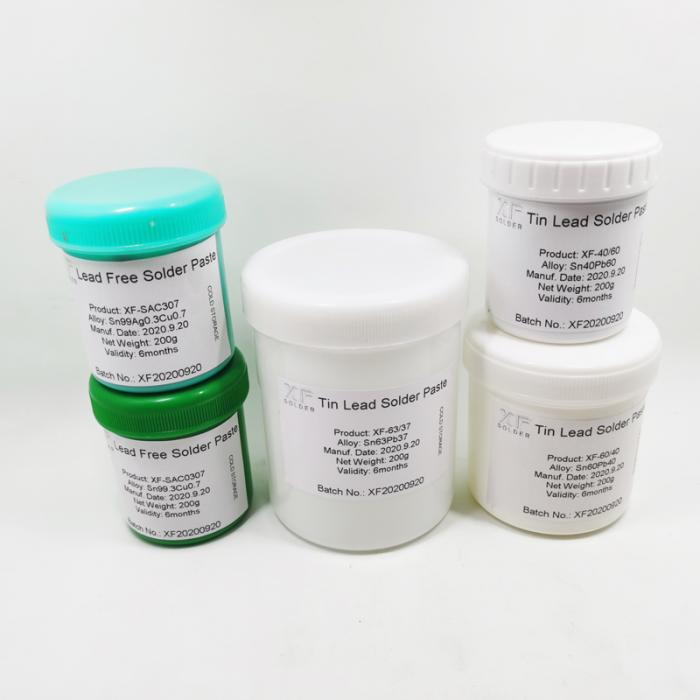

Alloy: Tin lead alloy: Sn63Pb37, Sn60Pb40,

Sn50Pb50, Sn40Pb60 solder paste etc; Lead free alloy: Sn42Bi58,

Sn96.5Ag3.0Cu0.5, Sn99Ag0.3Cu0.7 solder paste etc.

Powder size: Type 3 (25 to 45 microns); Type

4 (20 to 38 microns); or other powder size upon requests.

Flux: around 11.5%, no clean type.

Packing: Jar & Syringe.

Weight: 100g, 200g, 500g, 1000g per jar or

other weights available upon requested.

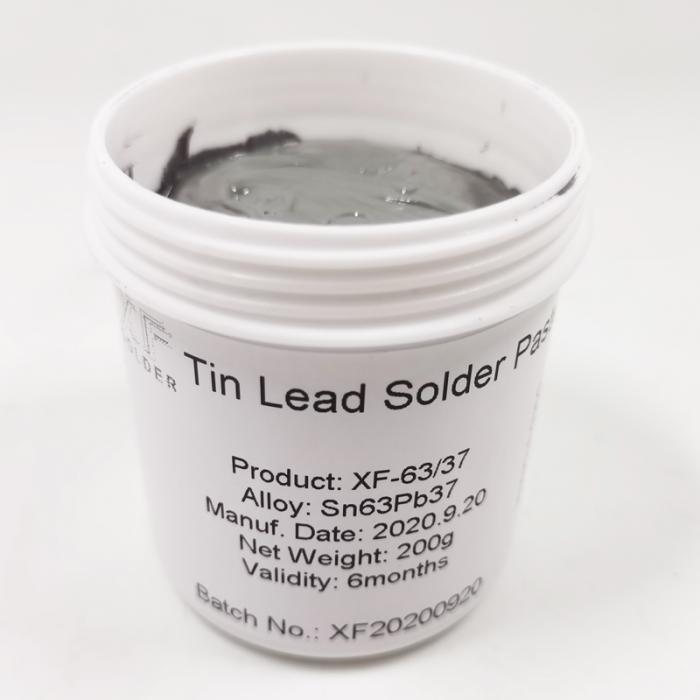

Appearance: metallic grey color pasty form.

Applications of Solder Paste:

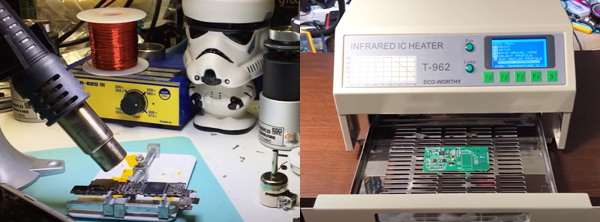

Solder paste generally is used in SMT

soldering projects, it’s applied onto printed circuit board (PCB) through a stencil

printing process. Stencil is generally a stainless steel that is cut and

perforated with desired pattern which will allow the solder paste to be applied

on the pads precisely & with accurate amount of paste. Alternative ways to apply

solder paste will be jet printing through nozzles or applied manually by using

syringe packing. After that the PCB will be heat up (reflow soldering) so that

the solder paste will melt to connect the electronics components with the pads.

Using & Storage of Solder Paste:

1. Solder paste should be stored

in refrigerator at temperature between 0 to 10℃ to have longer

shelf life.

2. Solder paste should be taken

out of refrigerator 3 to 6 hours prior to use so that it has enough time to

turn to room temperature and function properly.

3. In case there’s still leftover

paste after use, it must be tightly sealed and refrigerated. Before re-using,

it’s a must to double check if the solder pastes hasn’t become separated or

thicken to its usual state.

4. Read TDS of each type of solder

paste before using.